UPDATED: February 10, 2016

This page includes troubleshooting tips for common paper issues (such as paper jams and stops) that can occur in the feeders and insert areas of your DI425 FastPac™ Inserting System and DI380 OfficeRight™ Inserter.

Look through the list for help with common issues, and tips to prevent paper jams and misfeeds with your DI Inserter:

A. Envelope Feeder

B. Materials Feeder

C. Insert Area

TIP: Jams and crooked folds may start in a different area of the machine than where the issue is initially discovered. It is a good practice to check that the side guides are set properly when these issues occur.

A. ENVELOPE FEEDER

PROBLEM - Envelope stops in flap opener.

Possible causes and solutions:

- Clear flapper of stopped material - If material stops in the flapper it must be removed properly to clear the system of damaged material and resume normal operation. How to remove a stalled envelope from the flapper on the DI425 (video).

- Misaligned envelope side guides - The guides keep the envelope straight as it travels through the system. Over time, the guides may shift and impede insertion. How to load the envelope feeder on a DI380 (video) and How to load the envelope feeder on a DI425 (video).

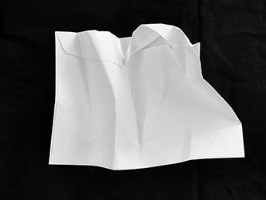

- Poor material condition - Good material condition can help avoid paper stoppages. Aerate and neatly stack your paper to facilitate separation when feeding. Remove material with warped or flared edges as it can produce misfeeds and jams. Best practices for material storage and safe handling (video).

- Poor roller condition - Toner buildup or worn edges can diminish the roller's ability to grasp or drive the material correctly. Visually inspect the roller and clean or replace if necessary.

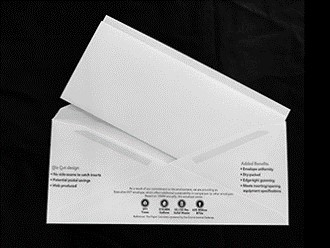

- Material specifications - Envelope specifications must be followed for the system to run properly. Machinable envelopes with proper depth and flap shape are required. Refer to the Envelope Specifications section to be sure you are using proper envelopes for your machine.

B. MATERIALS FEEDER: This section covers issues that can occur in your machine's material (sheets and inserts) feeders.

TIP: Jams and crooked folds may start in a different area of the machine than where the issue is initially discovered. It is a good practice to check that the side guides are set properly when these issues occur.

PROBLEM: Crunching paper or crooked paper as feeder feeds.

Possible causes and solutions:

- Misaligned sheet feeder side guides - The guides keep material straight as it travels through the system. Over time, the guides may shift and impede insertion, causing crooked folds. How to load the insert feeder on the DI380 (video) and How to load the insert feeder on the DI425 (video).

- Poor roller condition - Toner buildup or worn edges can diminish the roller's ability to grasp or drive the material correctly. Visually inspect the roller and clean or replace if necessary.

- Poor material condition - Material stored for long periods of time or stored in damp environments may curl and low humidity environments can cause paper to stick. Check the material condition before loading. Best practices for material storage and safe handling (video).

- Material specifications - Material specifications and recommendations must be followed for the system to run properly, enabling material to run smoothly through the machine. Refer to the Material Specifications section in the operator guide to learn more about proper material specifications.

C. INSERT AREA: This section resolves issues that can occur in your machine's material insert area. For troubleshooting tips, find your problem in the following list.

TIP: Jams and crooked folds may start in a different area of the machine than where the issue is initially discovered. It is a good practice to check that the side guides are set properly when these issues occur.

PROBLEM - Envelope side collision with straight or correct fold.

Possible causes and solutions:

- Misaligned envelope side guides - The guides keeps the envelope straight as it travels through the system. Over time, the guides may shift and impede insertion. How to load the envelope feeder on a DI380 (video) and How to load the envelope feeder on a DI425 (video).

- Material handling - Good material condition can help avoid paper stoppages. Aerate and neatly stack your paper to facilitate separation when feeding. Remove material with warped or flared edges, as it can produce misfeeds and jams.

- Poor material condition - Envelopes stored for long periods of time or stored in damp environments may curl or stick. Before loading, check the box of envelopes for damaged pieces, extra glue, or envelopes sticking together.

- Poor roller condition - Toner buildup or worn edges can diminish the roller's ability to grasp or drive the material correctly. Visually inspect the roller and clean or replace if necessary.

PROBLEM - Envelope side collision with crooked insert fold.

Possible causes and solutions:

- Misaligned sheet feeder side guides - The guides keep insert material straight as it travels through the system. Over time, the guides may shift and impede insertion. How to load the insert feeder on the DI380 (video) and How to load the insert feeder on the DI425 (video).

- Material specifications - Material specifications and recommendations must be followed for the system to run properly and for material to run smoothly through the machine. Crinkled, wrinkled and curled paper can cause crooked folds.

- Poor roller condition - Toner buildup or worn edges can diminish the roller's ability to grasp or drive the material correctly. Visually inspect the roller and clean or replace if necessary.

PROBLEM - Material not inserted and sitting on top of envelope.

Possible causes and solutions:

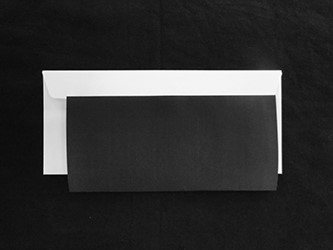

- Envelopes flaps are not opening - Open the flap of the envelope manually before loading. How to load pre-flapped envelopes on the DI380 (video) and How to load pre-flapped envelopes on the DI425 (video).

- Poor material condition - Envelopes stored for long periods of time or stored in damp environments may curl or stick. Before loading, check the box of envelopes for damaged pieces, extra glue, or envelopes sticking together.

PROBLEM - Material catches on or "splits" throat of envelope.

Possible causes and solutions:

- Poor material condition - Envelopes stored for long periods of time or stored in damp environments may curl or stick. Before loading, check the box of envelopes for damaged pieces, extra glue, or envelopes sticking together. Best practices for material storage and safe handling (video).

- Envelopes flaps are not opening - Open the flap of the envelope manually (or pre-flap) before loading

- Envelope specifications - Envelope specifications must be followed for the system to run properly. Machinable envelopes with proper depth and flap shape are required. How to identify problem envelopes and learn specifications for the DI380 or DI425 inserters (video).

- Envelope testing - Try a different type of envelope (within specification). If the problem improves, it may be the envelope. If the problem does not improve, it could be one of the other causes described here.

- Poor roller condition - Toner buildup or worn edges can diminish the roller's ability to grasp or drive the material correctly. Visually inspect the roller and clean or replace if necessary.